Controls Integration

Environ works closely with our customers, providing technology-agnostic solutions to meet their diverse range of needs. We provide an array of HMI, SCADA, PLC integration, and AI tools to optimize your water and wastewater treatment processes.

Problems we can help you solve:

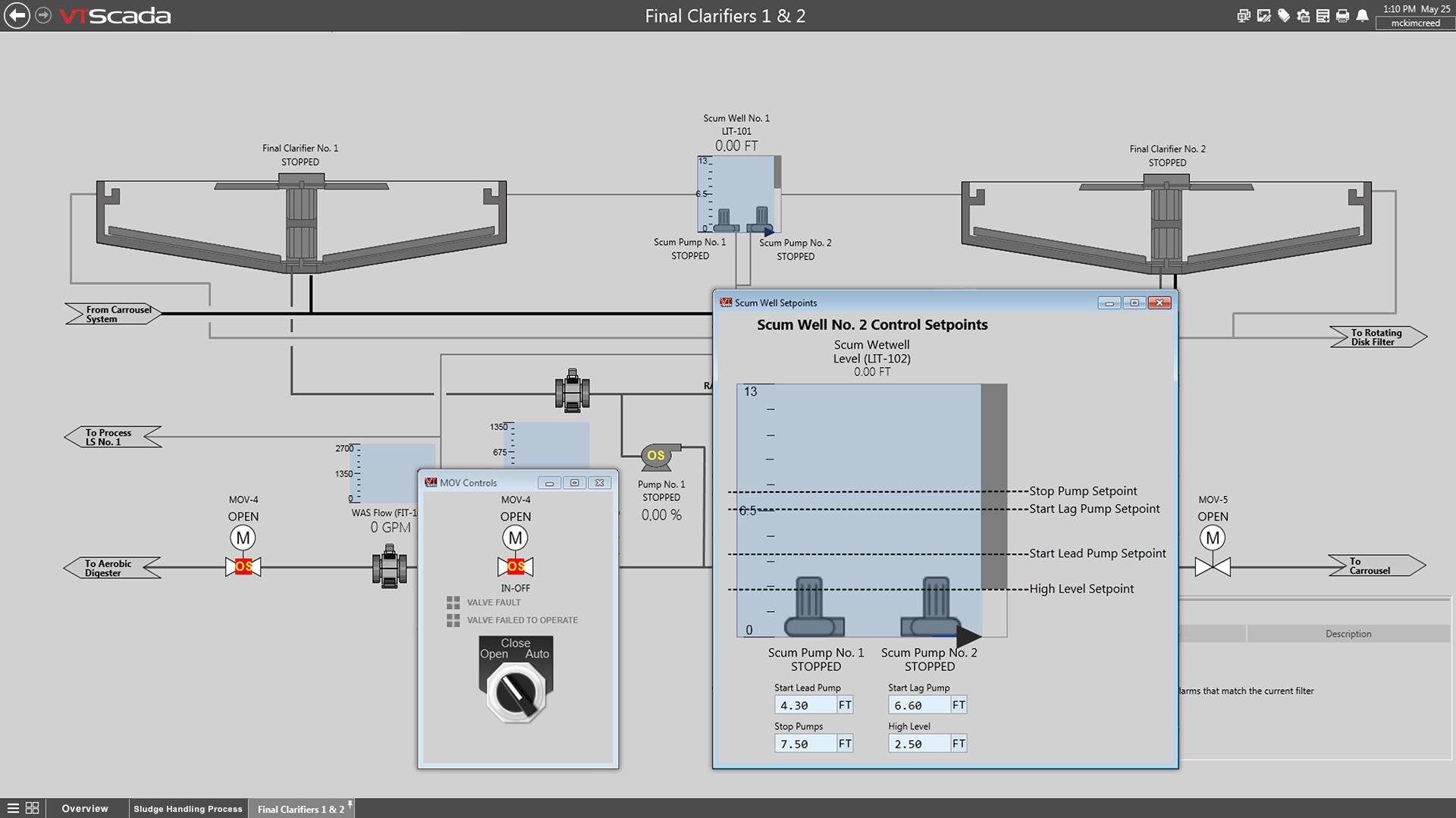

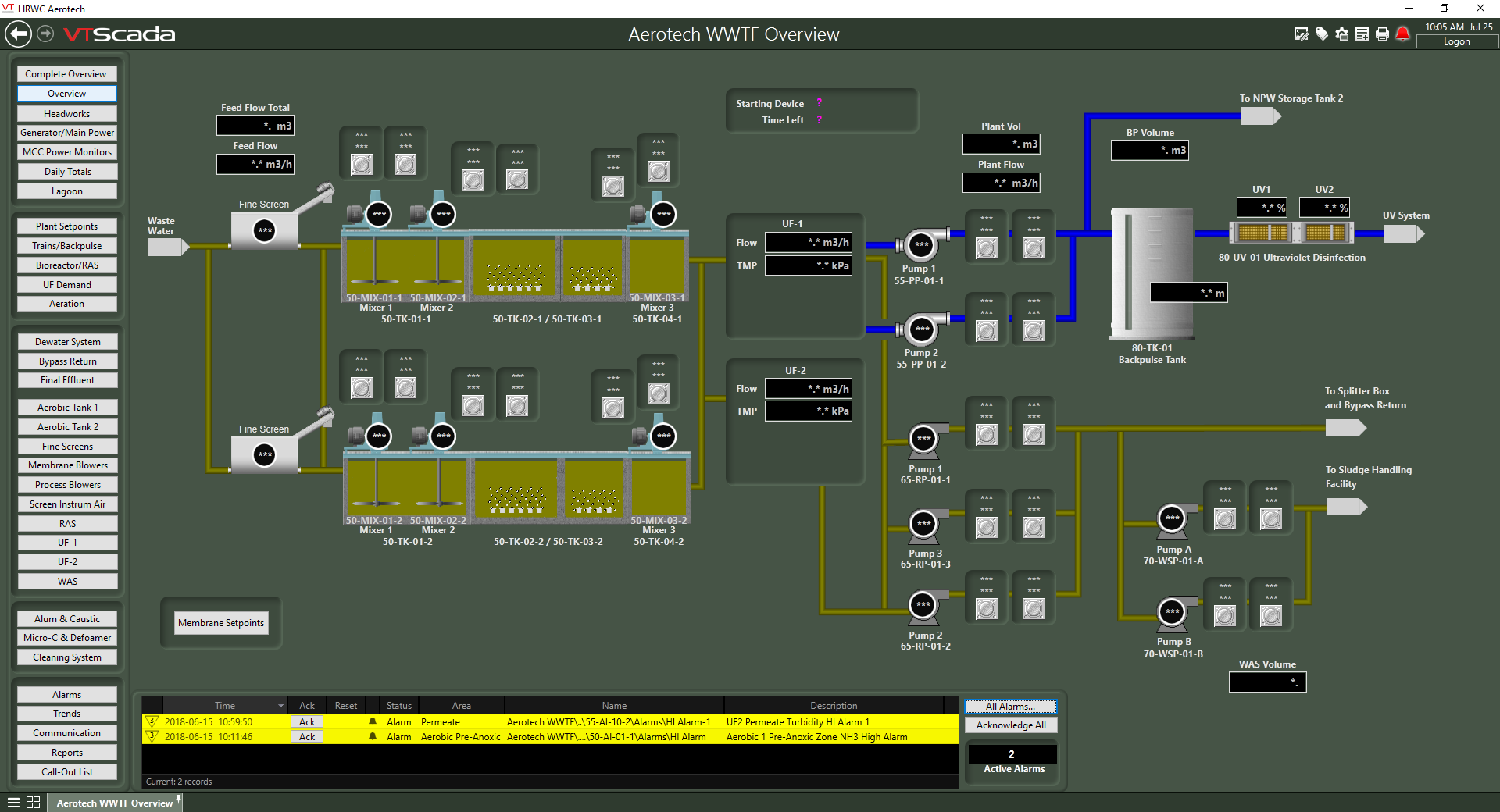

- Customized Human-Machine Interface (HMI) design and implementation

- Customized Supervisory, Collection and Data Acquisition (SCADA) design, and implementation

- Integration of on-site and off-site treatment, collection, and distribution systems

- PLC design, implementation, and integration solutions

- Compensate for knowledge loss and variability in operator experience levels

- Alleviate complete dependence on process screens that require training and experience to interpret

- Improve the process by reducing the reliance on individual operator experience to drive process outcome

Who We Serve

We work directly with end-users who have intimate operations knowledge and are close to the challenges they have with their plant and process systems in the following industries:

Food and Farm Waste-to-Energy

Public & Private Wastewater Treatment

Public & Private Water Distribution

Wastewater Resource Recovery

How We Work

We are not a training organization, and we are not a distributor of high-tech software solutions.

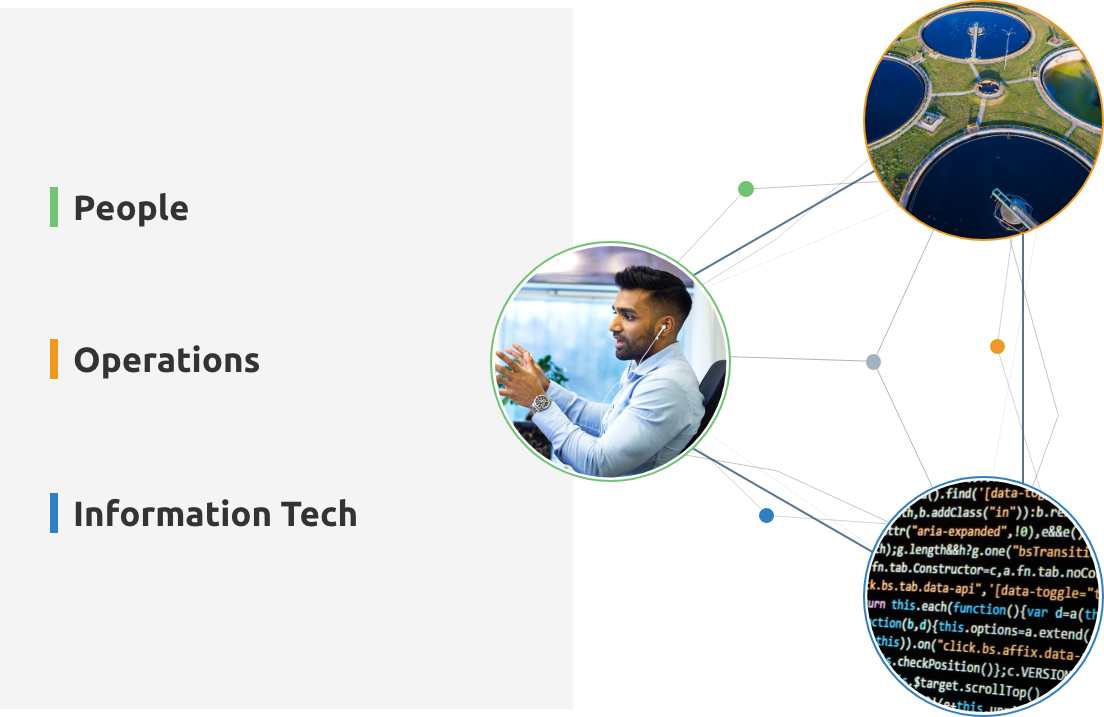

We believe that in any given industrial process there are three broad and interdependent components that each play an integral part in the success of the process: People, Operations Technology (OT), and Information Technology (IT). We like to show this relationship with what we call The People-OT-IT Triangle.

The People-OT-IT Triangle

We develop tailored solutions, focusing on the ideal mix of People, OT, and IT for our customers allowing their operators and process engineers to achieve results in the most cost-effective manner possible. We believe the next level of innovation in our organizations comes from how we make our processes and systems more effective by finding the right combination of people and technology. Both need each other to be successful, thus they are not mutually exclusive resources.

People have the experiential “tribal knowledge” that is an integral part of our process effectiveness. Technology offers tools to share knowledge, integrate systems and best practices into operating scenarios, and make continuous improvements. The results are exponential benefits from consistent operations, retained knowledge, improved process efficiency, and more impactful O&M spending.